Adjusting the carburetor with a lambda sensor has never been so easy. MD-LAMBDA-VIEW, the universal data logger.

Do you drive a car or a motorcycle? Have you built or modified your vehicle with great attention to detail? Do you want to adjust your carburetor or fuel injection system yourself with a lambda sensor and have everything under control at all times without having to install bulky, unsightly displays or instruments?

With MD-Lambda-View, the universal, miniature data logger, a tiny RGB LED provides you with constant information about the current mixture composition. The RGB LED has a diameter of 5 mm and can be discreetly mounted on or inside the vehicle. You can access more data and the logging function via your mobile phone. The lambda value, engine speed, throttle valve position or carburetor slide position, and on-board voltage are continuously stored, visualized via a web interface, and stored in a table. The data can later be evaluated using common spreadsheet programs or with MD-Lambda-View 3D Surface .

HOW DOES MD-LAMBDA-VIEW WORK?

MD-Lambda-View is designed to read out a Bosch LSU 4.9 broadband probe. Furthermore, the speed, throttle valve or carburettor slider position and the on-board voltage are determined.

The lambda value is visualized via an RGB LED using different colors. This saves space without having to add additional clunky displays or instruments.

Data such as lambda value, speed, throttle valve or carburettor slider position and on-board voltage are displayed on your mobile phone or tablet via an integrated web server, permanently logged and can be exported as CSV for further processing.

WIRELESS

Connection to mobile phone, tablet or PC via integrated WIFI hotspot

EASY INSTALLATION

The connection to the vehicle is uncomplicated and quickly done for the experienced mechanic.

ALWAYS READY

MD-Lambda-View is operated via the on-board electrical system of your vehicle.

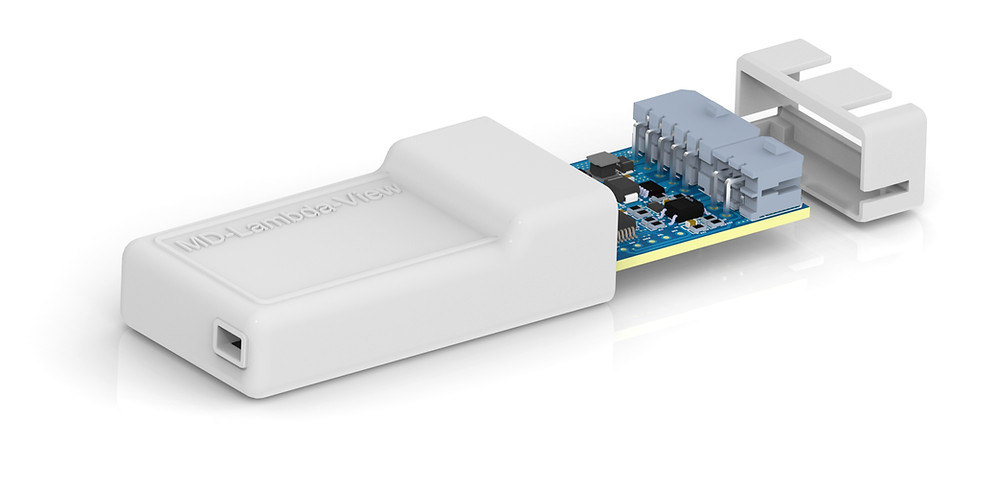

SMALL DIMENSIONS

MD-Lambda-View is 70mmx36mmx17mm (without wiring harness). MD-Lambda-View always finds a place.

SIMPLE USAGE

The visualization, operation, and adjustment via the web interface is intuitive and simple. No app needed!

HIGH COMPATIBILITY

MD-Lambda-View can be individually integrated into your vehicle environment using additional adapters.

MD-LAMBDA-VIEW IS REALLY SMALL

Dimensions: 70mmx36mmx18mm

Plastic housing with lid

circuit board

Connection cable (not shown)

MD-LAMBDA-VIEW

With MD-Lambda-View you have a full overview of important engine parameters:

Current lambda value

Engine Speed

Throttle cap or carburettor slider position

On-board voltage

With these values, any carburettor engine can be optimally adjusted. Export all data to Excel and create lambda mappings. See exactly where the mixture needs to be enriched or thinned down.

MD-LAMBDA-VIEW DATA EVALUATION

With MD-Lambda-View 3D-Surface you can visualize and analyze the stored logging data. Various settings help you to adjust the display of the data as optimally as possible to your needs. MD-Lambda-View 3D-Surface is a website that you can access in any browser and it is freely available.

Just click here to open MD-Lambda-View 3D-Surface in your browser and here to download a test CSV zip file.

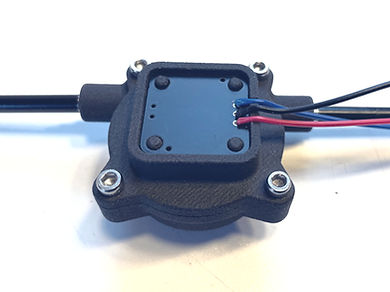

MD-LAMBDA-VIEW CABLE PULL SENSOR

The biggest problem in determining the throttle valve or carburetor slide position is attaching a suitable sensor to the throttle body or carburetor. With a throttle body, a sensor can be attached to the throttle shaft, but this requires some tinkering. With a conventional carburetor, the whole thing seems more complicated, if not impossible.

This is where the MD-Lambda-View cable sensor comes into play. This is installed in place of the standard throttle cable. The entire assembly behaves like a conventional throttle cable, but activates a position sensor driven by a cable guide. The position sensor operates contactlessly by detecting the magnetic field of a magnet located in the rotor. This means that all actions on the throttle grip are simultaneously transmitted to the carburetor slide or throttle valve, as well as to the integrated position sensor. I ultimately decided against using a potentiometer because it creates additional actuation forces and is very expensive in a waterproof version.